Alpine has produced 3 generations of the F#1 Status car audio systems. Each designed to be the absolute pinnacle of what is possible in a car audio system at that time. The first was a CD based stereo system, the next a DVD-Audio based 5.1 audio system and the current is a High resolution(384kHz 32 Bit) stereo system.

I was working at an Alpine F#1 Status dealer when the first 2 generations were launched and we sold and fitted them to several cars. At the time we were the only F#1 Status outlet in my country and worked closely with Alpine Japan. The president and head of engineering from Alpine Japan visiting our store on a few occasions.

Being a young worker at a car audio outlet at the time, I was unable to afford either of these cutting edge systems but was grateful to be involved with their installation and experiencing them first hand. Many years later when I found out a 3rd generation was being released, I decided I was going to move heaven and earth to be able to get myself this system. Ironically although I had done the original F#1 Status training and am quite capable of installing it, after over 40 years in car audio industry, the newest system is only allowed to be installed by an accredited F#1 Status dealer. I totally understand this and it wasn’t a problem as my F#1 status dealer is run by a guy I not only worked with but also trained, and have remained good friends with since that time.

This system isn’t something that is fitted in a few days and the process took several months but the results definitely justify the time it took.This obviously increases the cost as in my case a lot of custom installation was involved. This included 3D scanning my A pillar trims, so new custom trims could be made, which involved precise 3D printing of sections, so as to retain normal airbag function in the event of an accident. Note pic below was not the finished speaker pod as you’ll see in later pics

This 3D printed piece was so incredibly detailed, from the 3D scan that the factory trim clips were able to be used to fit it. This will insure airbags functionality won’t be compromised.

This pic shows the initial fabrication in the hatch area including the 2 amps and the processor, as well as the subwoofer box. The sub box took a great deal of work and time, as it is taken to a whole other level from here, including being shaped more and sprayed to match the cars factory paint.

Here you can see we needed to bond the 2 pieces we 3D printed to get a complete custom A pillar trim. This still isn’t the finished trim as many more hours were spent perfecting it before we flocked it(a coating) to make it look more factory

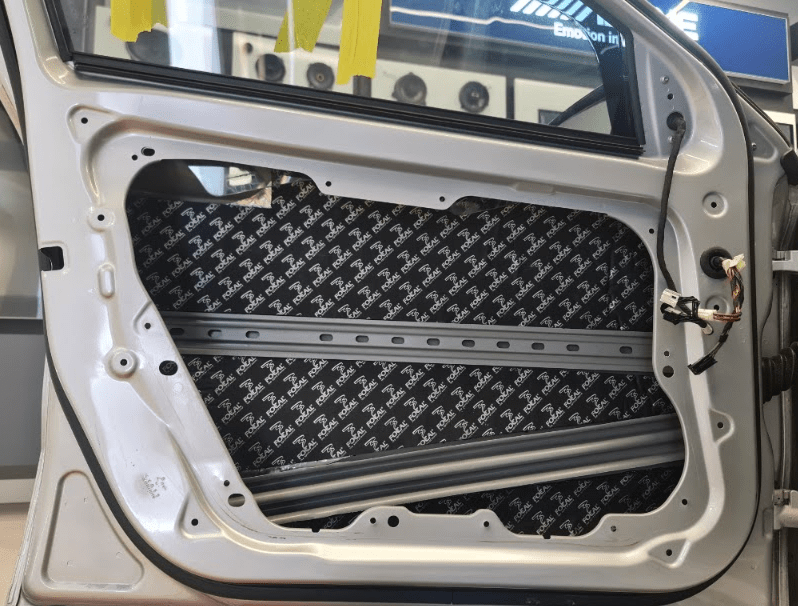

In this pic you can see the start of the sound deadening being applied. Although most door trims are held on with screws and clips. This one is riveted on, so the rivets needed to be drilled out and my installer actually had to buy a special riveting tool and special rivets, to be able to replace the unique factory rivets.

Below the amp rack, there is space for a very large lithium ion battery and the specialized electronics to charge and maintain it. This allows a fair bit of engine off listening time for demoing the system.

This pic shows the 6.5″ woofer. In all my years in car audio I have never heard a 6.5″ speaker get as low and deep as this one. Incredible midbass that makes it sound like an 8″ driver. Notice the Allen head bolts. It is the little touches that elevate a great installation.

Here is subwoofer box after lots of work and it was painted. If you compare it to first pic you can tell how much work went into getting it to look like this. Lots of filler and sanding.

The amp rack was also painted to match the cars paint.a lot of work for something underneath the amps and processor but its the little details that make the finished result so good

Here youcan see the false floor amplifier rack. The 2 amps are fitted at top and the processor in the middle. The trim piece here covered in vinyl will have glass fitted to it so this can all be on display

Here you can see the gear in place on amp rack. While the installation was happening the current president from Alpine Japan was visiting, so I asked if he would autograph my processor which he kindly agreed too.

Here is a pic of the 11″ subwoofer fitted in its custom enclosure. Again I am blown away by how incredible this speaker is and you would think it was a multiple sub set up from the sound and energy it produces.

Here you can see the glass was edge lit but I ended up turning that off as it highlighted any dust that is virtually impossible to eliminate in a normal car that is driven daily.

Here it is without edge lighting and I think this looks much better. We could have made beauty panels to cover all the wiring but I prefer being able to see it as wiring is a work of art.

We tossed a few ideas about where to fit the head unit/system controller pictured but instead of custom integrating it into the car, I managed to secure a 20+ year old Alpine goose neck mount originally designed to mount an EQ controller they made many years ago. I had actually been looking for this for several years, for an idea I had for my other car without any luck, when I found a guy who had a few NOS(new old stock) units. The odds of this were quite incredible but I was very fortunate. He also used one in the same way on the exact same system in another country. Great minds think alike, as they say.

In this pic you can see the goose neck but the controller wasn’t fitted ti it at this stage, hence the hand in pic holding it.

This pic shows the controller mounted and despite my fears, the goose neck is incredibly rigid and once set in position it will not move

In this pic you can see the flocking on the trim that helps it look factory and the gorgeous tweeter and midrange. The midrange sounds incredible and silky smooth as does the tweeter. The tweeter exhibits no harshness or brightness at even very high volume and the system is incredibly accurate and detailed across the range of music. The speakers completely disappear leaving the sound stage spread across the glass

Not a great pic due to reflections but here it is up and running.

The hatch area also has a carpeted MDF cover so there are no problems putting the shopping in there and other day to day practical things.

As this is an add on system(it keeps all the factory system in place), it has a function to mix the audio from the factory system into the music or feed it into this system. The Mix function is very handy as it allows me to use the factory satnav or take telephone calls without having to swap inputs.

After system was completed, it needed tuning of not only the overall sound but also the time alignment. The equipment used was well beyond what you would find in any normal car audio shop and was loaned from Alpine. It featured a dummy head with 2 inbuilt microphones in the ears and a dedicated processor, to accurately measure the timing and EQ results, and then that was used to help adjust the DSP time alignment and sound.

The dummy head was placed exactly where my head would be when sitting in the car. Then there was specific software to help read this data and also separate software to adjust the settings in the F#1 status system itself. The tuning was done over several days. Obviously I am incredibly happy with the results but also hearing what others think after a demo and seeing them blown away, and this is from experienced car audio sound quality competitors to others who have zero experience. It exceeds every ones expectations, so far. Playing anything, whether from Norah Jones, Kendrick Lamar, Billie Eilish to Dire Straights, if its well produced, it sounds amazing. The only thing I would say is a slight negative and I mean slight, is the volume control goes from 0 to 200 and so turning the volume up can take a few twists of the beautiful volume rotary control and is therefore slower than I’d like, but that is it and I can live with that

The system is unlike anything available and features advanced technology never seen in a car audio system before. The Digital Signal Processor(DSP) can make time adjustments that equate to 0.9mm so can be dialed in with more precision than we have ever heard before. Other systems the adjustments equate to 7.2mm, so this is 8 times more precise than other DSP units.

We use the time delay on certain speakers in a car, so the sound from the speakers that are different distances from our ears arrives at the exact same time. To achieve this it uses a more advanced crystal oscillator than has been used before. As oscillators will change their timing signal, as temperature changes, these units are fitted inside a heated chamber. Basically a highly regulated precision oven, so the temperature is constant even though the temperature in the car can very over an extreme range from below freezing to over 40-50 C and so remains exact and precise to a level never seen in car audio. The amount of data when using 384kHz 32 bit music is phenomenal and the system uses 4 advanced DSP processors that have 64Bit/1GHz processing power, 10 times the capability of other DSP units, so it can process high resolution signals without losing any detail and avoiding introducing any jitter(timing errors).

Below is directly from Alpines website

The Problem with Jitter

Jitter, or clocking errors, occur when samples of a digital recording become misaligned due to having several clock references in separate components – common in car audio. While the file is transmitted between components and converted from a digital file to sound you can hear, each sample references a point in time and uses an internal clock to determine when that data should be played. Using CD as an example, 44,100 samples must be aligned to the original recording each second. If any of these samples deviate from the exact moment in time they are supposed to play, you experience jitter – subtle distortions and loss of music detail. When considering the incredible sampling rates High-Resolution audio is capable of, i.e. 384,000 samples per second, the problem of jitter can become even more dramatic. With the new Master Clock Management System at the heart of AlpineF#1Status, all transmissions and conversions are completely synchronized by referencing a single “master clock,” virtually eliminating all jitter in audio transmission.

About the OCXO DuCULoN® Crystal Oscillator

At the heart of the Master Clock Management System, the OCXO DuCuLoN® crystal oscillator was engineered with incredible accuracy. This ultra-premium component is located at the center of the HDP-H900 Audio processor where all the tuning of sound occurs. Shielded by a copper plate, the crystal oscillator’s location is protected from the influence of noise and temperature fluctuations that may happen in the vehicle. Two quartz crystals are housed in a dedicated, heat-insulated case along with a temperature control circuit which allows it to have 500 times the accuracy compared to a standard crystal oscillator. Ambient temperature changes can cause up to .002% of deviation of accuracy. To reduce that fluctuation to 0%, the oscillator is heated when the power supply is turned on. Once its temperature reaches a level where the clock accuracy stabilizes, the “clock” indicator light on the Head Unit Commander turns on, and the temperature within the clock is kept constant.

About Time Correction

While accuracy and performance are important factors to consider in a car audio system, having properly tuned speakers will determine the overall sound quality. It is also important that the system has high-precision tuning features to ensure High-Resolution sound quality. Inside a vehicle, sound arrives at different times to the listener, due to the different positions of the high, mid, and low-frequency speakers and the asymmetrical distance between the driver’s seat and the right and left speaker placements. Along with the time misalignment, the frequency response can vary between left and right speakers due to reflections and absorptions in the vehicle. To account for these discrepancies, a digital audio processor (DSP) is incorporated to make time corrections and equalization to the speakers so that the appropriate sounds arrive at the listener’s ears at the same time. To reproduce High-Resolution sound, the speakers must be tuned accurately. The below diagram shows a case where the gap in the timing between the left and right speaker is large versus small. The gap in distance causes the sound waves from both speakers to cancel each other out and produce distortion, which greatly affects sound quality. While in traditional products, the gap can only be adjusted at 7.2mm steps (at an ambient temperature of 20°C), the AlpineF#1Status DSP can be adjusted at 0.9 mm steps, 8x more precise than traditional DSPs. Because the listener is likely to notice timing differences, particularly in the high-frequency range found in High-Resolution sound, micro-adjustment capabilities like this are crucial in the car interior space. To achieve more accurate sound tuning, AlpineF#1Status has incorporated four of the highest-quality digital sound processors (DSPs) capable of 64Bit/1GHz processing power, similar to a personal computer’s central processing unit (CPU). This processor has 10 times the capability of traditional Digital Sound Processors, allowing it to process High-Resolution, high-spec signals without losing sound details.

About Carbon Fiber Reinforced Plastic (CFRP)

Traditional speakers are made with optimized materials and a structure suited to the specific playback bandwidth. For example, if the diaphragm is thinned and its weight is reduced, it becomes optimal for high-frequency audio playback, but will also hurt its low frequency capabilities. If the diaphragm is thick and rigid, it becomes optimal only for low-frequency audio playback but too heavy to play high-frequency tones. The challenge during the speaker production process is selecting materials that complement the characteristics of the speaker while overcoming disadvantages during playback. In other words, the material of the speaker directly impacts the sound during playback. To tackle this issue, AlpineF#1Status unified the tones of the speakers by unifying their material and structure. After extensive research, the best result was using Carbon-Fiber Reinforced Plastics (CFRP). With a lightweight, yet highly rigid material, CFRP is used as the diaphragm for speakers ranging from the ultrahigh frequency tweeter to the low frequency subwoofer. This is the first time the same cone material has been used throughout the entire system from tweeter to subwoofer in the car audio industry.